According to statistics, there are 283 million vehicles in China as of 2016, and the number of 140,000 vehicles is increasing every year. In the era of pursuing fashion and individuality, GUBOT manufacturers are also constantly innovating. According to statistics, 60% of the market It is a spray hub, 30% is a brushed wheel hub, and 10% is a plated wheel hub. With the improvement of the quality of life, more people are pursuing personality and high-end, "buy the horse, you have to match the saddle" Already in the real situation to a real consumer behavior, the vast majority of car owners will be re-constructed, therefore, the wheel repair machine is in a new industry and has great potential for development!

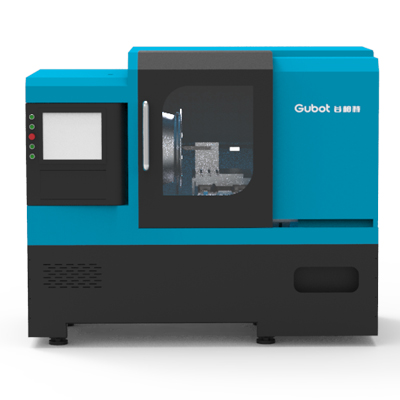

In response to the market trend, GUBOT convened the factory R&D personnel for the first time. After repeated research and testing, the R&D personnel finally designed a powerful, stable and high-capacity wheel repair machine in 2016.

Advantages of GUBOT wheel repair machine:

1. The lathe rotates at a high speed, and the working state can reach 2500 rpm or more, and the rotational speed is adjustable.

2. High degree of automation, can adapt to complex wheel hub machining, only need to use the "take the hub curve" function for different hubs to obtain the processing data of the hub, and can save the obtained curve data for repeated processing. You can also use the original data processing provided by our company.

3. Easy to use, the entire lathe is easy to use and simplifies operation. It can be used with a little training.

4. Super stability, independent research and development, using precision parts to create a cost-effective alloy wheel repair machine.